Scientists have created what is believed to be the toughest material on Earth by combining three metals; specifically, chromium, cobalt, and nickel, that get sturdier in colder temperatures.

The alloy that combines the three metals is known as CrCoNi and experts found that it has the highest toughness ever recorded on our planet. The material has impressive ductility and strength, and what scientists are calling "outstanding damage tolerance."

Toughest Material on Earth

The team of scientists from Lawrence Berkeley National Laboratory (Berkeley Lab) and Oak Ridge National Laboratory published the study that described the findings as "record-breaking."

The Governor's Chair for Advanced Alloy Theory and Development at Oak Ridge National Laboratory and the University of Tennessee, Easo George, said that in the design of structural materials, scientists want them to be strong but also ductile and resistant to fracture.

The scientists' study examined the fracture toughness values of the CrCoNi alloy, which is a subset of metals called high entropy alloy (HEAs). These types of alloys are made of an equal mix of each constituent element, as per NDTV.

These balanced atomic recipes appear to provide some of these materials that have extraordinarily high combinations of strength and ductility when exposed to stress.

While HEAs have been a prime focus of research studies since being first developed nearly two decades ago, the technology that is required to push the materials to their limits in extreme tests has only recently become available.

A senior faculty scientist in Berkeley Lab's Materials Sciences Division and the Chua Professor of Engineering at UC Berkeley, Robert Ritchie, who is a co-leader of the research, said that the toughness of the newly-developed material near liquid helium temperatures reached as high as 500 megapascals square root meters.

According to Science Alert, George said that when developing structural materials, experts typically compromise between strength and ductility. Furthermore, the material is unique because instead of becoming brittle when cold, it becomes tougher.

Combination of Metals

George and Richie have spent some time working on a class of materials, including CrMnFeCoNi, which is a combination of chromium, manganese, iron, cobalt, and nickel. This one in particular has been the subject of intense study after scientists noticed that its strength and ductility go up at liquid nitrogen temperature without seeing a reduction in its toughness.

CrCoNi is one derivative of this alloy and was able to show scientists even more exceptional properties than the original. In comparison with other real-world materials, the new alloy dwarfs them in toughness as the aluminum airframe in passenger airplanes was only measured at 35 megapascals and some of the best steels were only at around 100 megapascals.

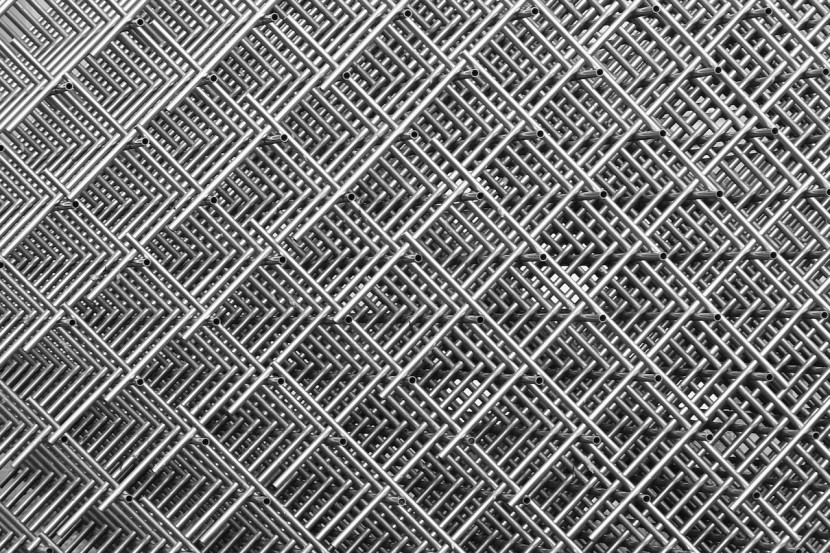

Many solid substances, including metals, exist in a crystalline form that is largely characterized by a 3D atomic pattern, which is known as a unit cell and makes up a larger structure called a lattice. The physical properties of the lattice determine the material's strength and toughness or lack thereof.

Because there can be no "perfect" crystal, unit cells are bound to have "defects," the most prominent of which are dislocations. These are boundaries where undeformed lattice meets up with deformed lattice, SciTechDaily reported.

Related Article : Scientists May Have Figured Out a Way To Detect Elusive Dark Matter Using Quantum Computers

© 2026 HNGN, All rights reserved. Do not reproduce without permission.