Injection molding is a popular and inexpensive way for plastic parts to be made. In contrast, sheet metal fabrication is a common and economical way of manufacturing metal products. Quality and long-lasting parts can be produced quickly and with great precision. With the advent of online production platforms, placing an order for your product has been simplified.

What Are the Benefits of Sheet Metal Fabrication?

Here are several advantages of using this manufacturing process:

1. Precision and Accuracy: Computerized designs being produced using computerized equipment makes the fabrication process efficient and accurate. CNC punch presses and laser cutters can do their work quickly, with very tight tolerances. Computer operated presses can turn sheet metal into the desired shape repeatedly and consistently.

2. Durable Yet Shapeable: Sheet metals are strong and can withstand a lot of pressure, while at the same time, they can be pressed into almost any shape. This makes them an ideal material for innovative designers and engineers to use.

Sheet metals can also be treated using various methods to make their surface more durable. The finishing process can make them resistant to the sun, water, and corrosion.

3. Wide Range of Materials to Use: A variety of metals can be used such as mild steel, stainless steel, or aluminum. The thicknesses you can choose from is 1/2mm up to several millimeters, depending on your need.

What Are the Different Types of Sheet Metal Fabrication Processes?

A combination of several fabricating processes can be used to make a product out of sheet metal. Here is a brief look at several of them:

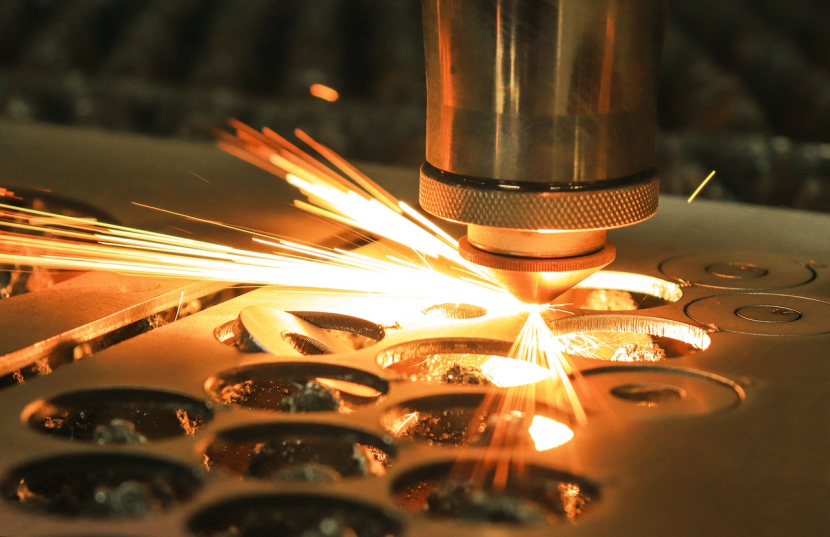

1. Laser cutting: CNC laser cutters can quickly and precisely cut out intricate parts, leaving clean edges.

2. Punching: Punches and dies are used to make the desired hole in a sheet of metal or to punch out the shape of the part needed.

3. Folding: Certain sides or areas of a part may need to be bent or folded over. A variety of shaped bends can be made by using dies and a brake press.

4. Stamping: Stamping creates a raised section in the metal.

5. Welding: Various types of welding methods are used to join two pieces of metal together. Different methods are needed based on the metal used and product application.

What Are the Four Types of Steel?

Steel is an alloy made from iron mixed with carbon, and sometimes with other elements. The concentration of each element determines the grade of steel. Here is a brief look at each:

1. Stainless steel: Stainless steel is shiny, strong, and corrosion-resistant. It can withstand high temperatures. With over 100 grades, stainless steel is an extremely versatile metal.

2. Carbon steel: Carbon steel has a matte and dull appearance. It is susceptible to corrosion. It comes in three grades: low, medium, and high carbon steel.

3. Alloy steel: Alloy steels have a mixture of several metals. It normally is low-cost steel and is commonly used in mechanical works and car parts.

4. Tool steel: Tool steels are hard, durable, and heat and scratch-resistant. It is commonly used to make metal tools; so, therefore, the name.

Given the variation of metals available, a wide range of processing methods, and the accuracy with which products can be made, sheet metal fabrication is the manufacturing process of choice for a lot of metal products. Now that you can order your manufacturing online, both injection molding and sheet metal fabrication, getting your products made is easier than ever.

© 2026 HNGN, All rights reserved. Do not reproduce without permission.