Can You 3D Print a 3D Printer? Learn How to Do It Now

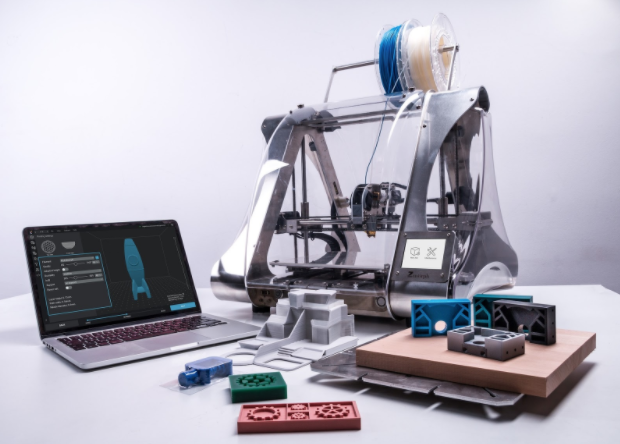

3D printing is a fascinating technology, as it allows you to replicate almost anything. And, it would even be more awesome if it can self-replicate. So, can you 3D print a 3D printer?

This is an age-old question in the 3D printing industry, and the answer depends on one's perspectives. But one thing is for sure. We have just barely scratched the surface of this technology. The possibilities are endless.

Why Should You Build a 3D Printed 3D Printer?

While it’s highly convenient to fabricate your own products using a 3D printer, buying this piece of equipment can be quite costly. In fact, the price of this type of printer can go as high as several thousands of dollars, and buying it can really put a dent on your budget.

On the other hand, building your own 3D printer is more budget-friendly. Instead of shelling out thousands of dollars on buying a new one, you can just spend hundreds of dollars for the parts and assemble them. Essential components, such as the frame, stepper motors, extruder, end stops, and print plates, can be purchased at affordable prices on online markets.

Aside from the cost benefit, there’s also the easier and better prototyping process that you can enjoy with this type of printer. Unlike traditional printers, 3D printing machines can guarantee fast and precise fabrication of prototype designs. As a result, you can easily transform ideas into perceptible prototypes that you can use to attract clients to invest in your business.

What Type of 3D Printer Should You Use?

You may be wondering how to 3D print a 3D printer. But before you get ahead of yourself, you first need to learn the basics, starting with the different types of 3D printers.

Fused deposition modeling (FDM)

This 3D printing technology is commonly used for plastic parts. It uses a quick and affordable method for producing physical models. However, its uses are quite limited because the parts lack strength and have rough surface finishes.

Stereolithography(SLA)

SLA printers produce very detailed parts, with tight tolerance and smooth surface finishes. Aside from the high-quality surface finishes, the parts are also quite functional. That’s why these printers are widely used in the medical field. Some of its common applications include microfluidics and anatomical models.

Selective laser sintering (SLS)

SLS produces parts that are made from real thermoplastic material. This means you get parts that are both durable and functional. Unlike other 3D printed parts, SLA parts are strong enough to be used to nest multiple parts in a single build without any support structures.

Digital light processing(DLP)

DLP 3D printers have the ability to image a complete layer of a build at the same time. This results in improved prototyping speeds. The DLP printing technology is often used for rapid prototyping, but it's higher throughput makes it perfect for low-volume manufacturing of plastic parts.

Other types of 3D printing technologies are:

Multi jet fusion (MJF)

PolyJet

Direct metal laser sintering (DMLS)

Electron beam melting (EBM)

If you want to create a DIY 3D printer, you'll need to familiarize yourself with these 3D printing technologies. Likewise, you should also know using a digital servo drive in your 3D printer can improve its printing capabilities.

3D Printing a 3D Printer: Is It Possible?

So, can you 3D print a 3D printer?

There are already self-replicating 3D printers in existence. However, they still can't print the whole thing. You will have to print the parts individually and assemble them yourself. Furthermore, there are still several parts that can't be 3D-printed, such as the electronic components. So, yes. You can 3D print a 3D printer—but not entirely. At least, not for now.

Where to Get Model Blueprints

Building a 3D printed 3D printer frame can be quite a challenge, especially if you don't have a design model. So, for you to print anything, you'll need a good blueprint.

Making your own models

When asking yourself "can I 3D print a 3d printer?", the first thing you need to do is learn how to create a model blueprint. Creating your own model? Don't let that intimidate you. There are free web-based design tools that enable you to create 3D objects even if you don't have a degree in computer-aided design (CAD). One example is Autodesk's Tinkercad.

Printing downloaded models

If you're not yet ready to create your own blueprint, many sites offer downloadable 3D models for 3D printing. Some are free, while others are payable.

These websites include:

Cults 3D

Pinshape

3DShook

Thingiverse

3D Warehouse

However, you'll be limited to the available designs. If you're serious about 3D printing, you'll have to learn to design your own model. This is especially true if you want to answer the question "can you 3D print a 3D printer?" with a "yes".

Printing scanned objects

If you’re wondering whether or not you can simply scan real objects and print them, the answer is an absolute “yes”! There are many ways to create a 3D model, and 3D scanning an existing object is one of them.

To start 3D scanning, all you need is your phone camera, a little technique, and some free or inexpensive software. Capturing a 3D image of an object will take a bit of practice. But, in time, you'll be able to master it.

Where to Buy the Materials

The best place where you can get 3D printer materials will depend on your needs and budget. An acrylonitrile butadiene styrene (ABS) or polylactic acid (PLA) filament spool can cost between $10 and $20 depending on where you buy it. You might still be able to find someone selling filaments for less. However, if you're looking for conductive or metal-infused wood or ABS thermoplastics, then expect them to be a little more expensive.

Below are some excellent places where you can buy 3D printing materials.

Amazon

eBay

NinjaTex

FilaFlex

3D-Printer-Filaments.com

Conclusion

3D printing a 3D printer is possible. However, the current 3D printing technology still has many limitations. For starters, you can't simply print the whole thing at one go. You'll have to print each part and put them together yourself. The electronic components, such as the motor, are also not reproducible using the printer. But, who knows what the future holds?

For more interesting topics about technology, check more of our tech news.

© 2026 HNGN, All rights reserved. Do not reproduce without permission.