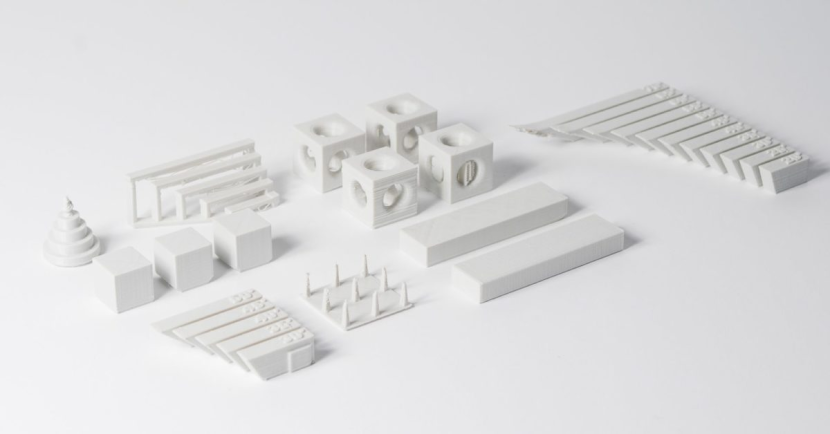

Rapid prototyping is the group of techniques used to fabricate a scale model of a physical product using 3-Dimensional CAD (Computer Aided Design) data. Additive manufacturing and 3-Dimensional printing have become basically synonymous with rapid prototyping because these processes provide a prototype that is close to the finished product with a small amount of time and money.

Rapid prototyping gained prominence because traditional prototyping was prohibitively expensive when done well, and functionally useless when done with makeshift proof-of-concept models and basic tools. Basically, to make a good prototype you had to spend almost the same amount of money as you did on the real thing, but to make a less expensive prototype was not worth the time or money because it was not similar to the real thing. Rapid prototyping services continue to grow in importance for product designers and engineers in numerous manufacturing sectors today. The following is a list of the top 10 tips to reduce the cost and lead time of rapid prototyping.

1. Is rapid prototyping the right service for your business?

For manufacturing and software companies who need to show proof of concept before a large rollout, rapid prototyping is the right move. It quickly produces a high quality prototype at scale without breaking the bank.

2. Choose the right technology and machinery for your project.

Decide what is most important for your prototypes and choose the right equipment for the job. If the overall prototype is more important than the details, focus on equipment that can produce the most accurate product quickly. If details are the most important, find the equipment that can produce the highest quality prototype.

3. Make your parts hollow if they can function correctly in that state.

Hollow parts in a prototype mean you can create the overall idea of what the product will look like and how it will perform at a fraction of the cost. With the knowledge that the hollow parts will not be hollow when it is time for production, you can create a top notch prototype with less raw materials which will decrease costs, workload to the machinery and the time needed to complete the project.

4. Optimize the design

Pay attention to detail by creating air holes for hollow designs, eliminating angled walls, using wall thickness above minimum specifications, etc. By optimizing the prototype design you can create a good prototype without the headaches.

5. Automate the post-processing involved with 3-Dimensional printing when possible.

If you can automate the post-processing rather than doing everything by hand, you should. Post-processing is both necessary and time consuming and doing whatever you can to lessen the time and labor involved is important.

6. Assemble large parts from multiple smaller prints rather than printing the entire product as a whole.

It is easier, in the long run, to print small jobs and assemble them later than to print an entire product and then have a post-processing nightmare. By assembling smaller jobs, you lessen the likelihood of errors and keep an eye on quality control throughout the production.

7. Optimize the schedule

By printing small batches during the day, large builds at night, and using multiple printers to divide the workload, you can optimize your printing schedule. Optimization of your schedule will decrease the turnaround time and keep costs as low as possible throughout the process.

8. Prevent failures with proper machine upkeep, attention to detail and using reliable raw materials.

Do not skimp on the details. If you use poor raw materials or you do not keep your equipment functioning at a high level, you will increase the risk of failure. You do not want to save a little money on the front end just to lose a lot later in the process.

9. Call 3D Hubs for your rapid prototyping needs.

3D Hubs is a leader in rapid prototyping and can help outsource any large or small jobs associated with your work. Call us with a design idea and we can quickly draw up a plan and provide your company with a quote to get started as soon as possible.

The major benefits of rapid prototyping are two-fold and very simple to comprehend: Time and Money. When introducing a new product or a new software, time and money are the two things that you cannot afford to waste. With rapid prototyping you can produce a high quality product in very little time and for a fraction of the cost that companies paid in the past. While other benefits such as producing high quality prototypes that mirror the actual product, the time and money saved are the biggest benefits.

Contact 3D Hubs for all of your rapid prototyping needs. 3D Hubs has been at the forefront of CNC rapid prototyping and SLS rapid prototyping for years. Not only can 3D Hubs handle rapid prototyping, but they can take that prototype and manufacture, in bulk, the product that you are taking to market.

© 2025 HNGN, All rights reserved. Do not reproduce without permission.